Manufacturing Method

Sand Casting(Resin Sand, Pre-Coated Sand, Clay Sand, Water glass sand)

Material Standard

GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI, etc

Weight Range

1 kg to 100 Tons

General Casting Tolerance

CT8-CT12

Design Software

UG, Pro-E, Inventor

Dwg Format

STP, STEP, IGS,STP,X_T ,DXF,DWG , Pro/E, PDF, SLDPRT

Mould Manufacturing

Yes

Casting Stimulation

Yes

Ultimate machining tolerance

0.005mm

Quality Control

RT,UT,MT,PT,CMM,SCAN,Chemical and Mechanical Property Testing,Spectrometer,etc

Finish Roughness

Ra12.5-Ra25 according to customer requirement

Heat Treatment

Normalization , Annealing, Quenching and Tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching,etc

Surface Treatment

Shot/sand blast, Polishing, Surface Passivization, Painting , Anodizing,Powder coating, ED- Coating, Chrome Plating, zinc-plate, Dacromat coating, Finish Painting,hot-dip galvanizing, etc

carbon steel, low carbon steel, middle carbon steel, G35, G45, WCB, WCA, WCC, ISO 340-550, etc.

Alloy Carbon steel: G25CrMo4, Heat Resistant Steel, etc.

Stainless Steel: SUS 304, 304L, 316, 316L, CF8, CF8M, G-X7CrNiNb1189, etc. AS2074 or according to customer specific requirement.

Leesh is a professional and leading manufacturer of sand casting metal parts(ferrous and non ferrous) in Gray iron, ductile iron, malleable iron, carbon steel, stainless steel, aluminum, bronze, brass, zinc and all carbon and alloy steels.

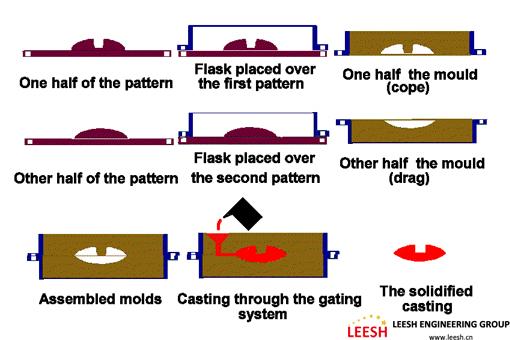

Sand Casting Process:Hand Molding and Auto-Molding Line

Sand Specification:Green Sand and Resin Sand

Standard: JIS, DIN, ASTM, BS and special material requirements.

Services: Design,OEM,Samples making,manufacturing

Sand Casting Principle

Contact: Betty Cao

Phone: +86 138 4009 6762

Tel: +86 138 4009 6762

Email: info@leesh.cn

Add: No. 16-97 Pufeng Road, ShenBei New District, Shenyang, China