Services

Forging

Forging Services

Precision Forging Solutions for Various Industries

Forging Classification

Hot Forging

Process performed at temperatures above recrystallization temperature, typically between 1000°C and 1300°C for steel. This allows for significant plastic deformation with minimal force.

- High formability

- Reduced tool wear

- Improved mechanical properties

- Suitable for complex shapes

Cold Forging

Process performed at room temperature or slightly elevated temperatures below recrystallization. Produces high precision components with excellent surface finish.

- High dimensional accuracy

- Superior surface finish

- Increased strength

- Material savings

Warm Forging

Process performed at intermediate temperatures between cold and hot forging, typically 300°C to 900°C. Combines advantages of both cold and hot forging processes.

- Lower forming forces than cold forging

- Better surface finish than hot forging

- Reduced springback

- Energy efficient

Open Die Forging

Process where metal is shaped between flat or simple contoured dies without completely enclosing the material. Ideal for large components and custom shapes.

- Large part capability

- Custom shapes

- Improved material properties

- Cost-effective for small quantities

Closed Die Forging

Process where metal is shaped between two or more dies that completely enclose the material. Produces complex shapes with high precision and repeatability.

- Complex geometries

- High precision

- Excellent surface finish

- High production efficiency

Ring Rolling

Specialized forging process used to produce seamless rings of various sizes and cross-sections. The process involves rolling a pre-formed ring between rotating rolls.

- Seamless rings

- Uniform grain structure

- High strength

- Cost-effective for ring shapes

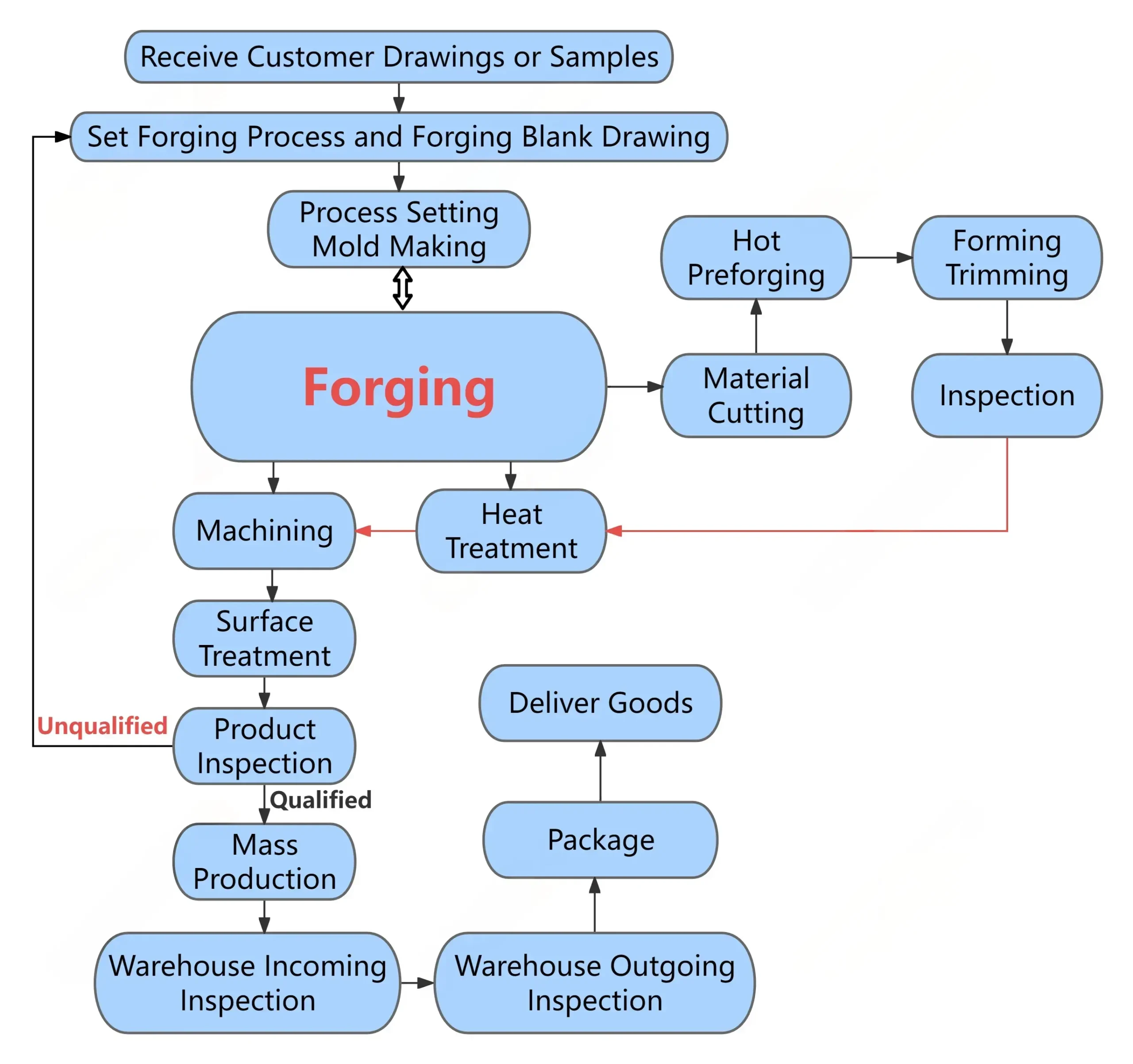

Our Forging Process

Comprehensive Manufacturing Process

Our forging process ensures the highest quality standards from design to delivery. We follow a systematic approach to produce precision components that meet or exceed customer expectations.

- Design & Engineering: Customized designs based on customer requirements

- Material Selection: High-quality alloys and steels for optimal performance

- Heating: Controlled heating to achieve proper forging temperature

- Forging: Precision shaping using advanced forging techniques

- Heat Treatment: Controlled cooling and heat treatment processes

- Machining: Precision machining to meet exact specifications

- Quality Control: Rigorous inspection and testing procedures

- Surface Treatment: Various finishing options for corrosion resistance

Forging Product Categories

Auto Parts Forgings

Precision forged components for automotive applications including gears, shafts, flanges, and various engine parts. Our automotive forgings meet strict quality standards and performance requirements.

- Engine components

- Transmission parts

- Suspension components

- Braking system parts

Agricultural Machinery Forgings

Durable forged parts for agricultural equipment designed to withstand harsh working conditions. Our agricultural forgings provide reliable performance in farming machinery.

- Tractor components

- Harvester parts

- Plow components

- Irrigation system parts

Construction Machinery Forgings

Heavy-duty forged components for construction equipment such as excavators, bulldozers, and cranes. These parts are engineered for maximum strength and durability.

- Excavator bucket teeth

- Crane hooks and shafts

- Bulldozer blades

- Loader components

Railway & Train Forgings

High-precision forged parts for railway and train applications that meet strict safety standards. Our railway forgings ensure reliable performance and passenger safety.

- Train wheel sets

- Railway couplings

- Bogie components

- Brake system parts

Truck & Trailer Forgings

Robust forged components for heavy-duty trucks and trailers. These parts are designed to handle heavy loads and long-distance transportation requirements.

- Axle components

- Suspension parts

- Coupling devices

- Brake system components

Heavy Truck Components

Specialized forged parts for commercial trucks and heavy vehicles. Our components provide exceptional strength and durability for the most demanding applications.

- Differential housings

- Drive shafts

- Steering components

- Transmission parts

Technical Specifications

| Category | Details |

|---|---|

| Manufacturing Methods | Hot forging, cold forging, warm forging, open die forging, closed die forging |

| Materials | Carbon steel, alloy steel, stainless steel, duplex stainless steel, Hastelloy, Inconel |

| Standards | GB, ANSI, BS, DIN, JIS, ASTM, ASME, AISI |

| Weight Range | 0.1 kg to 50,000 kg |

| Tolerance | Up to ±0.005mm |

| Surface Finish | Ra3.2 to Ra12.50 as per customer requirements |

| Heat Treatment | Normalization, annealing, quenching and tempering, case hardening, nitriding |

| Quality Control | RT, UT, MT, PT, CMM, chemical and mechanical testing |

Our Capabilities

Custom Design

Tailored solutions based on customer specifications

Quality Assurance

Strict quality control throughout the manufacturing process

Fast Delivery

Efficient production scheduling for timely delivery

Competitive Pricing

Cost-effective solutions without compromising quality

Technical Support

Expert engineering assistance for product development

Global Service

International shipping and support services