Services

Sand Casting

Sand Casting Services

Sand casting is a casting method in which the mold is made of sand to produce castings. The molding material for sand casting is widely available, inexpensive, and the equipment is simple and easy to operate. It is not limited by the type of casting alloy or the shape and size of the casting, and is suitable for various production scales. Therefore, sand casting is the most widely used casting method, with sand-casting parts accounting for about 80% of all castings.

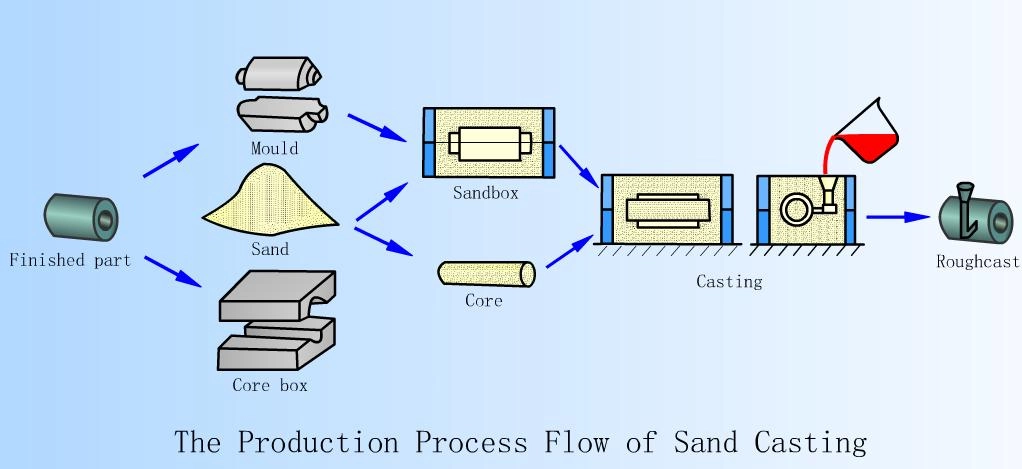

The process of sand casting is shown in Figure below. First, a pattern is made based on the part drawing, and then a sand mold is made by using the pattern and the sand mixture. For castings with hollow shapes, a core box and a sand core are also needed to be made by using the core box and the sand core mixture. Then, the molten metal is poured into the mold cavity. After the molten metal solidifies in the mold cavity, the sand mold is knocked off, and remove the casting riser and running system. Finally, the casting is cleaned of any residues, inspected, and can be delivered as the required casting.

Leesh holdings owns 2 automatic production lines for casting steel and casting iron.The materials we supply are Carbon Steel, Alloy Steel, Stainless Steel, Grey Iron, and Ductile Iron in accordance with the specifications of ASTM, SAE, AISI, ACI, DIN, EN, ISO, and GB standards. The mass range from few kilos to dozens tons.

Cast Steel

Casting weight: 50Kg- 25,000Kg

Casting Process: water glass quartz sand, alkali phenolic resin sand, coated resin sand (Hot-Box & Shell Molding)

Popular Materials: –Carbon steel: WCB, WCC,LCC, LCB, 1020, 1025,1040, 1.0619;

–Alloy Steel: 8620, 8630, 4140, 4130, 4320

–Stainless steel: ASTM A351 CF8, CF8M, CF3, CF3M, 4A, 6A

–AS2074

Cast Iron

Casting weight: 0.1Kg- 3,000Kg

Casting Process: resin sand, green sand

Popular Materials: — Grey iron: ASTM A48 Cl.20,25,30,35,40,GG20,25,30,35;

— Ductile iron: ASTM A536 60-40-18, 60-42-10,70-50-05,GGG40,GGG50,GGG60

Reliable and cost-effective metal casting solutions using green sand, resin sand, and dry sand processes for diverse industries.

About Our Sand Casting

We specialize in producing high-quality castings using various sand casting methods. Our flexible production capabilities allow us to serve industries including construction, machinery, automotive, and energy.

Why Choose Our Sand Casting?

- Cost-effective for small to large production runs

- Suitable for a wide range of metals and alloys

- Flexible design and size capabilities

- Shorter lead times for prototype and bulk production

Technical Capabilities

| Feature | Specification |

|---|---|

| Max part weight | 0.1 kg – 25,000 kg |

| Dimensional tolerance | CT8–CT12 (per ISO 8062) |

| Surface roughness | Ra 6.3–25 μm |

| Materials | Gray iron, ductile iron, carbon steel, alloy steel, aluminum |